Defect of the Month

Back to AGR's Library

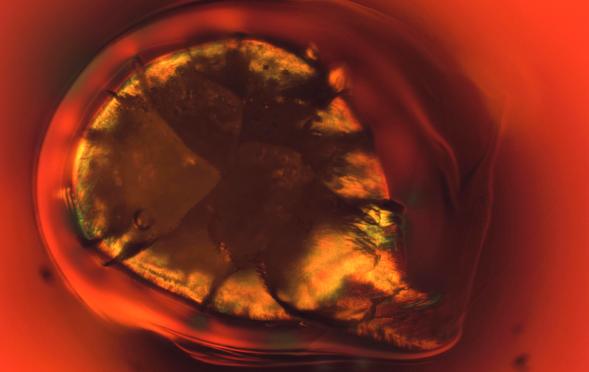

It’s May, the official start of the summer grilling season when backyard grills will be fired up across America. This particular image of a stone in glass resembles a grilled chicken breast slathered in barbeque sauce – although maybe we’re just a little hungry. In any case, the colorful fringe around the stone consists of feathery nepheline crystals (Na2O·Al2O3·2SiO2), which were created by an aluminosilicate refractory stone dissolving in the surrounding glass. Aluminosilicate, or mullite, type refractories are most commonly used in the forehearths of container glass furnaces. The surface cracks around the stone are caused by high stresses due to differences in the coefficient of thermal expansion between glass and refractory materials.

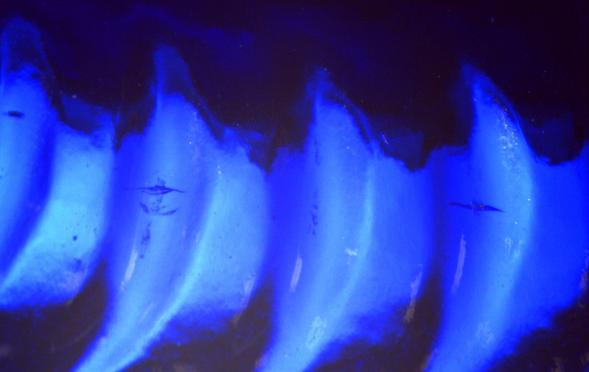

In this magnified view of a cobalt-colored bottle, a series of individual knurls are partially illuminated as large blue crescents. The smaller, vertical cracks running through two of the knurls are flaws referred to as “bearing surface checks.” Bearing surface checks are most often created when rough handling causes damage to the bottom soon after bottle formation. This damage is then extended into checks due to thermal stresses caused by temperature differences between the glass and the transfer or conveyer surfaces. Bearing surface checks may lower the performance of a container subjected to loads such as impact, internal pressure, and thermal shock.

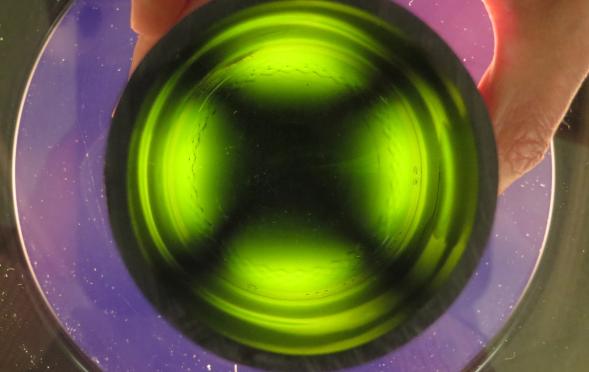

What do leprechauns and annealing stresses have in common? They’re both invisible! Or at least, usually invisible. This photograph shows the bottom portion of a green glass bottle under polarized light (crossed polars), which is necessary to view annealing stress. The bright “four-leaf clover” pattern is due to a combination of retardation caused by annealing stress and the optical configuration of the polarimeter. Following procedures described in ASTM C148, the amount of retardation can be measured and assigned an integer value called a “temper grade,” which is a good metric for annealing quality.

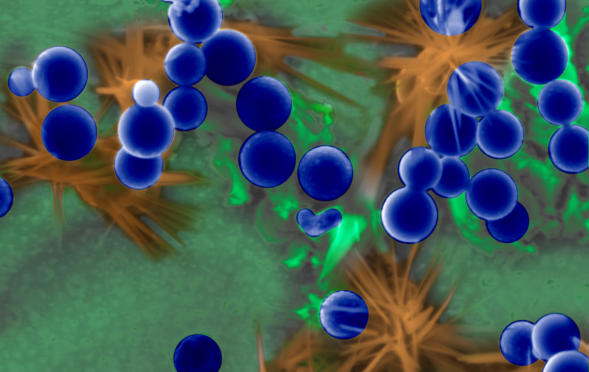

Like the John Steinbeck novel of the same title, this colorized SEM image has virtually nothing to do with grapes. When an organic (i.e. carbonaceous) material such as rubber, oil, or grease enters a bottle in the hot-end of a glass plant, temperatures in excess of 700°C cause it to instantly combust. Under some conditions, soot particles can be produced due to the condensation of vaporized organic matter. The spherical soot particles in this image (blue/purple) were created by combustion of an organic contaminant inside of a glass bottle. The radiating needle-like clusters (brown) are composed of sodium carbonate (Na2CO3), likely due to sodium in the burning material. The background (green) is an amorphous carbonized residue.

Pagination

- Previous page

- Page 4

- Next page